Description

Share to:

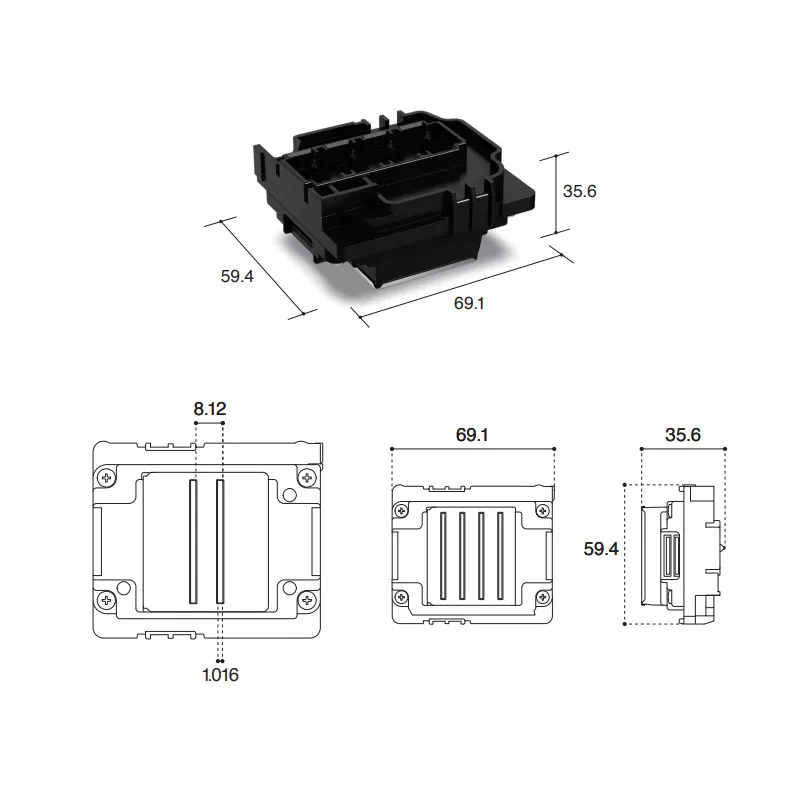

The Epson authorized iI3200-A1 Water is a cost-effective 1.33inch-wide MEMs head series providing high productivity and high image quality with (600 dpi/colour) high-density resolution. This printhead is suitable for water based inks. Ink ejection of up to 4 colours realize with high resolution .PrecisionCore print head has proven high durability and extended service life by Epson’s industrial printers

| Product Specifications: | |

| Product name | EPSON i3200-A1 |

| Ink Type | Aqueous |

| Type | PrecisionCore MicroTFP printhead |

| WidthxDepthxHeight | 69.1x 59.4 x 35.6 mm |

| Number of Nozzle | 3200 |

| Nozzle pitch/nozzle row | 1/300 inch |

| Nozzle rows | 8 rows |

| Nozzle Resolution | 300 npi /row 600 npi/2 rows |

| Max. number of colour inks | 4 colours |

| Droplet volumes | 6 pl (Single mode) |

| 6.3,1 2.3 pl (Multi mode) | |

| Technical Specifications | |||||

| Model | OR-2215TX | OR-2216TX | OR-2220TX | OR-2224TX | |

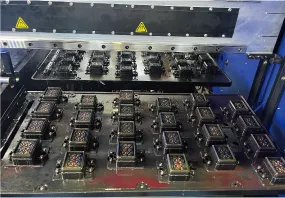

| Print Head | Type | I3200-A1 Print Heads | |||

| Head Number | 15 | 16 | 20 | 24 | |

| Ink Size | 3.5dpi | ||||

| Printing Speed | 1 Pass | 550 sqm/h | 600 sqm/h | 800 sqm/h | 860 sqm/h |

| 2 Pass | 275 sqm/h | 300 sqm/h | 400 sqm/h | 430 sqm/h | |

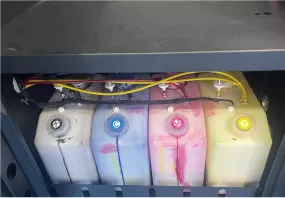

| Ink | Kind | High-Concentration heat transfer ink | |||

| Color | C M Y K | ||||

| Ink Supply Method | Positive pressure ink | Negative pressure ink | |||

| Capacity | 12 L | ||||

| Machine Width | 2250mm | ||||

| Print Width | 2200mm | ||||

| X-Axis Transmission | Maglev | ||||

| Receiving and Dischange Structure | Rear release / Frequency conversion motor | ||||

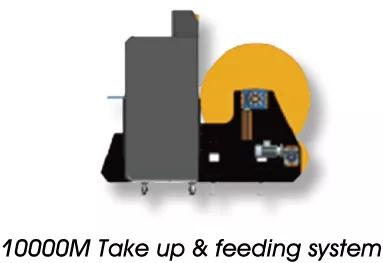

| Carryable Materials | 10000 Meter | ||||

| Material Specifications | ≥30g | ||||

| Drying Structure | External mulyi-stage automatic control wind and heat all-in-one dryer | ||||

| Moisturizing Structure | Fully Automatic Cleaning And Moisturizing Components | ||||

| RIP | Standardly equipped with and ruiyin beidou verison | ||||

| Computer Configuration | Operating System | Win7-64-bit / Win10 64-bit | |||

| Hardware Requirements | Hard disk:500G above(SSD is recommended);Running more than 8G memory; graphics card:ATI discrete graphics 4G memory;CPU:i7 processor | ||||

| Interface | Lan | ||||

| Power requirement | Input Voltage | AC 220 V± 5%, 16A, 50 HZ± 1 | |||

| Printer | 7500W | ||||

| Drying unit power | Maximum 18kw | ||||

| Machine Size/Weight | 4550(W)*2550(H)*2050(D) mm/1450 kg | ||||

| Package Size/Weight | Machine:4600(W)*1200(H)*2000(D)mm/1300 kg 10000 meters of retraction:2700(W)*1140(H)*1200(D)mm/300 kg | ||||

| Working Environment | Temperature 20℃-32℃, Humidity: relative humidity: 40%-65% (No condensing) | ||||

| Standard Components | Intelligent drying system,continuous ink supply system,ten thousand meters of unwinding negative pressure device,magnetic suspension motor module,etc | ||||

Technical characteristics of print head configuration

It adopts advanced board control technology, equipped with 20/24 i3200-A1 print heads and 3.5pl ink droplets.

The industrial-grade design ensures the durability of the print head. The new automated production scheme,

high-strength industrial design structure, can be equipped with 10000 meters of raw paper with performance,

and the unattended automated production scheme can be fully realized, so that the productivity

has been further improved.

■ After placing and receiving device, equipped with 10,000 meters of whale rall of base paper carrying performance;

■ High stabilty & High qualty accessornes are more durable, and improve the stabllty of printing to ensure high-quallty continuous output;

■ Air channel honeycomb platform, smooth feeding, paper is not easy to drum, improve output quallty,

platform calibration and adjustment more convenient;

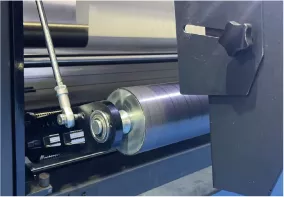

■ The rubber roller is more uniform, high-precision cutput, and is not easy to press wheel printing and paper wrinking;

■ Thickened wall panel structure, long-term high-speed operation stable, can carry more heavy rewinding material;

■ The front bottom and the back part are dried in one, which is more convenient for loading and unloading materials,

improve drying efficiency, and is more suitable for mass production of customers;

■ High-precision printing, fine patterm, natural transition, highly realistic;

■ Can better meet the needs of mass produciion, save loading and unloading time, improve production eficiencey;

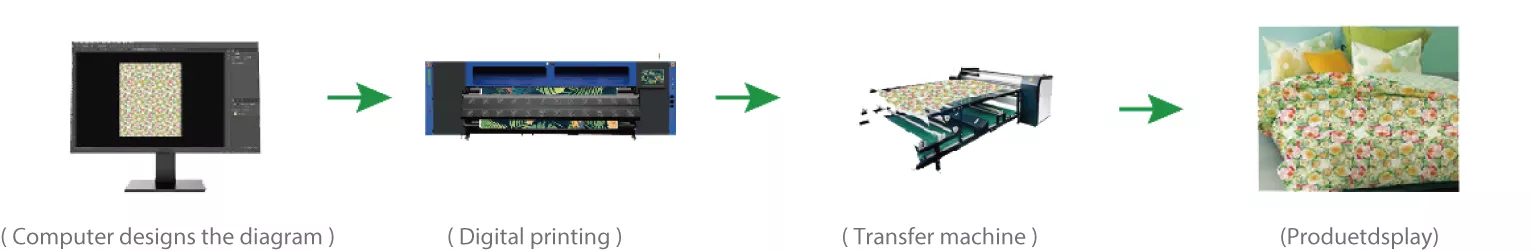

Latest technology of DTF , Want some quality clothing shirt? Try our DTF Print, same as silkscreen.

High quality THK sient lnear motor,lownoise,high precision,durable;

Automatic clearing and moisturizing

components ensure cleaning stability and prowide a higth quality working environment;

Three stage pressure wheel iting structure for more stable material feeding;

Paper retracting system adopts industrial servo dnve reducer,which has high speed, high precision and more stable paper retracting;

Front,middie and bottom mut seclion diying,high-speed prnting state,let the picture diy immediately;

24heads Upgraded swing bar and cylinder drive media tension to ensure smoother paper feeding under high-speed printing conditions;

Negative pressure ink supply unit,efficient and statde long time printing ink;

12L continuous ink supply system, with negative pressure ink path, can bestabie for a long time printing ink, noftying ink.

Widely used : household goods,clothing,masks,T-shirt printing,canvas bags,cushions, luggage products,flags,curtains,doors and Windows,sofa table mats, umbrella tents and other textile fabrics.