Description

Share to:

The Epson authorized iI3200-A1 Water is a cost-effective 1.33inch-wide MEMs head series providing high productivity and high image quality with (600 dpi/colour) high-density resolution. This printhead is suitable for water based inks. Ink ejection of up to 4 colours realize with high resolution .PrecisionCore print head has proven high durability and extended service life by Epson’s industrial printers

| Product Specifications: | |

| Product name | EPSON i3200-A1 |

| Ink Type | Aqueous |

| Type | PrecisionCore MicroTFP printhead |

| WidthxDepthxHeight | 69.1x 59.4 x 35.6 mm |

| Number of Nozzle | 3200 |

| Nozzle pitch/nozzle row | 1/300 inch |

| Nozzle rows | 8 rows |

| Nozzle Resolution | 300 npi /row 600 npi/2 rows |

| Max. number of colour inks | 4 colours |

| Droplet volumes | 6 pl (Single mode) |

| 6.3,1 2.3 pl (Multi mode) | |

* Dual I3200 Print Heads Speed

360x1800dpi – 4pass 10 m²/h

720x1200dpi – 6pass 7 m²/h

| T-shirt Digital Heat Transfer Printing Machine | ||

| Model | OR-6202 | |

| Print Head | 2 I3200 Print Heads Optional | |

| Printing Technology | Piezoelectric Inkjet | |

| Acceptable Media | Width | 620 mm |

| Thickness | Maximum 39 mil(1 mm) | |

| Printing Width | 600 mm | |

| Ink Cartridges | Type | Transfer Pigment Ink |

| Capacity | Continual Ink Supply System ( 220ML ) | |

| Color | CMYK + W | |

| Applicable Medium | Transfer film | |

| Color Manage | ICC or density curve | |

| Media Heating System | Powder & color fixing machine | |

| Interface | RJ-45/LAN | |

| RIP Software | Main top | |

| Power Supply | 50HZ/60HZ,220V/110V/10A | |

| Environment | Temperature | 22℃ to 28℃ |

| Humidity | 40% to 70% | |

| Printer Dimensions(With Stand) | L1620mm*W620mm*H1280mm | |

| Packing Dimensions | L1700mm*W700MM*H720mm | |

| Weight | G.W : 230kg N.W :180kg |

| Shaking Powder and Color Fix Machine | |

| Model | H650 |

| Media Width | 0-600mm |

| Applicable Medium | Nylon, Chemical Fiber, Cotton, Leather, Swimwear, Wetsuit, PVC, EVA, etc. |

| Powder Control | Powder shake control, powder control, powder direction and volume control |

| Heating & Drying Function | Multi-stage heating system, drying, cold air fan function |

| Rewind Function | Automatic induction winding |

| Electrical Parameters | Rated Voltage: 220V Rated Current: 20A |

| Rated Power: 3.42KW Power Consumption: 1KW-2.5KW | |

| Packing Size & Weight | Standard with 2heads : 1800* 1130* 1150mm |

| G.W: 290kg N.W: 180kg | |

▼ Design Pattern

Use photoshop, illustrator or other software to design your pattern.

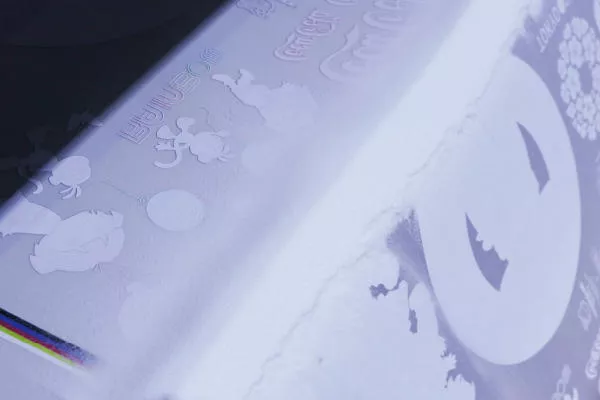

▼ Print Your Design

Adjust the printer parameters in the RIP software and use our printer and ink to print your pattern.

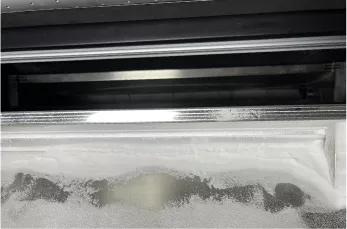

▼ Powdering

Turn on the switch of the powder shaking machine, the machine will automatically powdering, and dry and fix the color.

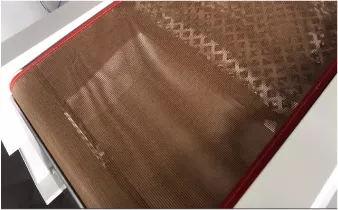

▼ Heat Press

Use a heat press machine, set the temperature to 180 degrees, and time 15 seconds to transfer.

Latest technology of DTF , Want some quality clothing shirt? Try our DTF Print, same as silkscreen.

Stable bulk system ensures amazing printing speed.

High-quality hot-melt powder, can be used repeatedly.

Commonly used products such as T-shirts, hats, backpacks, lanyards, shoes and more to create unique fashion pieces. It can also be used in denim clothes, non-woven bags, gift bags, pearl clothing, baseball caps, fabric gift boxes, etc. Make your travel outfit unique.

T-shirt Denim/Jeans

Canvas Hoodies

Sweaters and more……